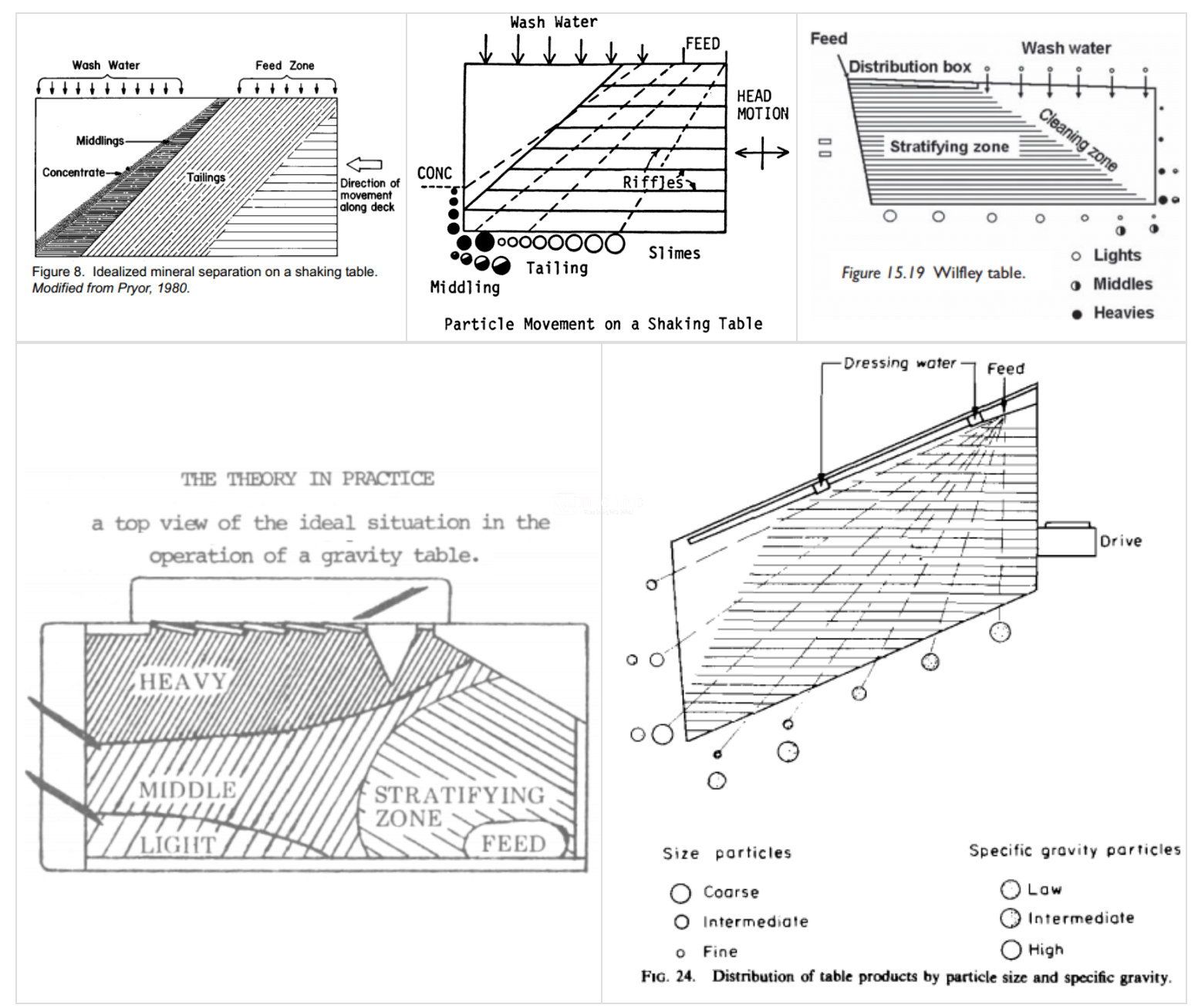

The working principle of shaking table(table concentrator) is to use the combined action of the specific gravity for different sorted minerals, alternating movement of bed surface, and transverse oblique water flow and riffle (or notch groove), to allow loose layering of ores on the bed surface and fan-shaped zoning.

1. Transmission

The transmission is of rugged construction and requires minimum maintenance. Its internal mechanism is splash lubricated from an integral oil pump.

2. Decks

The decks are built of 16 mm zircon-reinforced fiberglass with fabricated steel frames at the bottom and are easy to clean, not have common maintenance. The fiberglass decks have characteristic of water-resistance and corrosion-resistance.

3. Feed box and water box

A wooden feeding box with hooper ball mill and long water box are attached to the iron of deck, to make feeding evenly.

Nowadays, Shakinig Table more often to be used in Gold ore processing,due to it plays the essential role of classifing and used as heavy gold concentrating devices. Apart from nuggets; generally the valuable heavy minerals /metals like platinum and palladium that can be recovered by tables and sluices, On a gold sluice, large particles (gravel) travel by sliding and rolling over the riffles, with finer particles travelling by saltation. Sand travels by a combination of modes described earlier with some saltation over the riffles. Very fine particles are maintained in suspension by turbulent and inter-particle collision.

|

Model |

6-S 7.6 |

6-S 4.08 |

6-S 1.95 |

6-S 0.5 |

|||

|

Deck type |

Coarse ore Deck |

Fine sand |

Slime Deck |

Three different kinds of decks are available |

|||

|

Beneficiation Area (m 2 ) |

7.6 |

7.6 |

7.6 |

4.08 |

1.95 |

0.5 |

|

|

Deck Size |

Length (mm) |

4450 |

4450 |

4450 |

3000 |

2100 |

1100 |

|

transmission end width (mm) |

1855 |

1855 |

1855 |

1320 |

1050 |

500 |

|

|

Concentrate end width (mm) |

1546 |

1546 |

1546 |

1100 |

850 |

430 |

|

|

Maximum Feeding Size (mm) |

2 |

0.5 |

0.15 |

Sand -2 |

Sand -2 |

Sand -2 |

|

|

Feeding Amount |

30-60 T/d |

10-20 T/D |

15-25 T/D |

0.4-1.5 T/h |

0.3-0.8 T/h |

0.05-0.2 T/h |

|

|

Feeding Density (%) |

25-30 |

20-25 |

15-25 |

10-30 |

|||

|

Stroke (mm) |

16-22 |

11-16 |

8-16 |

6-30 |

12-28 |

9-17 |

|

|

Frequency (F) |

45-48 |

18-53 |

50-57 |

210-320 |

250-450 |

280-460 |

|

|

Water added |

80-150 T/d |

30-60 T/d |

10-17 T/d |

0.3-1.5 T/h |

0.2-1 T/h |

0.1-0.5 T/h |

|

|

Transverse slope of Deck |

2° 30-4° 30 |

1° 30-3° 30 |

1° -2° |

0-10° |

0-8° |

0-10° |

|

|

Longitudinal slope of Deck |

1.4 |

0.92 |

|

|

|

|

|

|

Cross-section Shape of Deck |

Rectangular |

Saw-tooth |

Triangle |

Available Rectangular, Saw-tooth, Triangle |

|||

|

Motor Power (Kw) |

1.1 |

1.1 |

1.1 |

1.1 |

1.1 |

0.55 |

|

|

Transmission Mechanism |

Eccentric linkage |

||||||

Shaking table (table concentrator) is one of the important dressing equipment that works depending on the gravity. It is widely used in selection of Tin, tungsten, gold, silver, lead, zinc, tantalum, niobium, iron, manganese, ferrotitanium and coal. The raw materials on the shaking table are with mixed densities, the suspending particles of the materials will leak down from the shaking table for its bearing the larger force. When the shaking table works, the raw materials on the table will tumbling and sliding with the table concentrator. The different speed of the particles will lead the table expanding, then the particles with smaller size will screening out. The raw mineral materials will be selecting by adjusting the speed of the table.

Shaking table, can handle with the size ranges from 2-0.037mm, also recovery of Au, Cu, Ag from various of slags, PCB, waste wire and cable, battery scrap, to improve recovery ratio and protect environment.

Recovery material size ranges are: coarse sand (0.5 mm to 2 mm);

fine sand (0.074 mm to 0.5 mm) and slime (-0.074 mm);

Effective mineral recovery size range is 0.22 mm to 2 mm.

Supply the most current design and technical expertise;Supply parts sales and training service far beyond the initial sale;Your profits with quality parts and expert service.